OUR HISTORY – BACK TO THE KEY DATE:

1964: The Valladolid Motores powertrain plant was founded, as FAMESA (Fabrication Mécanique SA).

1965: Started up operations.

1971: Construction of the Estudios building housing the new Research and Quality department, including Powertrain and Vehicle Engineering activities, to adapt Renault vehicles for the Spanish market. It started developing the Renault Siete (R7) in 1973, which enjoyed remarkable success and provided the basis for the 5-door R5.

1988: The Vehicle Product Engineering entity became BEA (Bureau d’Etudes Associé) and was combined with Central Product Engineering in France. It became Production Technologies Iberian Peninsula in 1991.

1993 to 1998: The DIM (Powertrain Engineering Department) was set up, bringing together Spanish and French teams to work on product and process engineering. This move brought about a significant leap in quality.

1998: Valladolid Motores started manufacturing the K4, a 16-valve engine developed by Renault, with output reaching 2,500 engines a day and 600,000 a year.

2001: Started up 1.5 dCi engine production.

2004: Reached a new engine production record: 1,071,018 units.

2005: Secured manufacturing approval for K9K Euro 4 step 2 engine.

2007: RTS (Renault Technology Spain) was set up to bring together all the powertrain and vehicle engineering teams in Spain, under unified human resources management. This entity included process engineering at the Tangiers plant until 2012.

2009: Launched H4J (TCe 130) engine production, reached 6 million K9 engine milestone.

2011: Reached 20 million engine production milestone, secured manufacturing approval for K9 Gen6 (Energy dCi 110) engine.

2012: Launched Energy K9 dCi 90, TCe 115 and K9K 450 production for Daimler.

2015: 50th anniversary, 25 million engine milestone.

2017: Launched a new generation of diesel engine (K9g8) and petrol engine (HR12, developed with Daimler).

2018: New high-pressure aluminium injection unit for cylinder blocks; launched new HR10 (1.0 TCe) and HR13 (1.3 TCe) petrol engines.

2020: New versions of Euro6D Full standard engines.

2021: Valladolid Motores became the only plant to produce K9 engines.

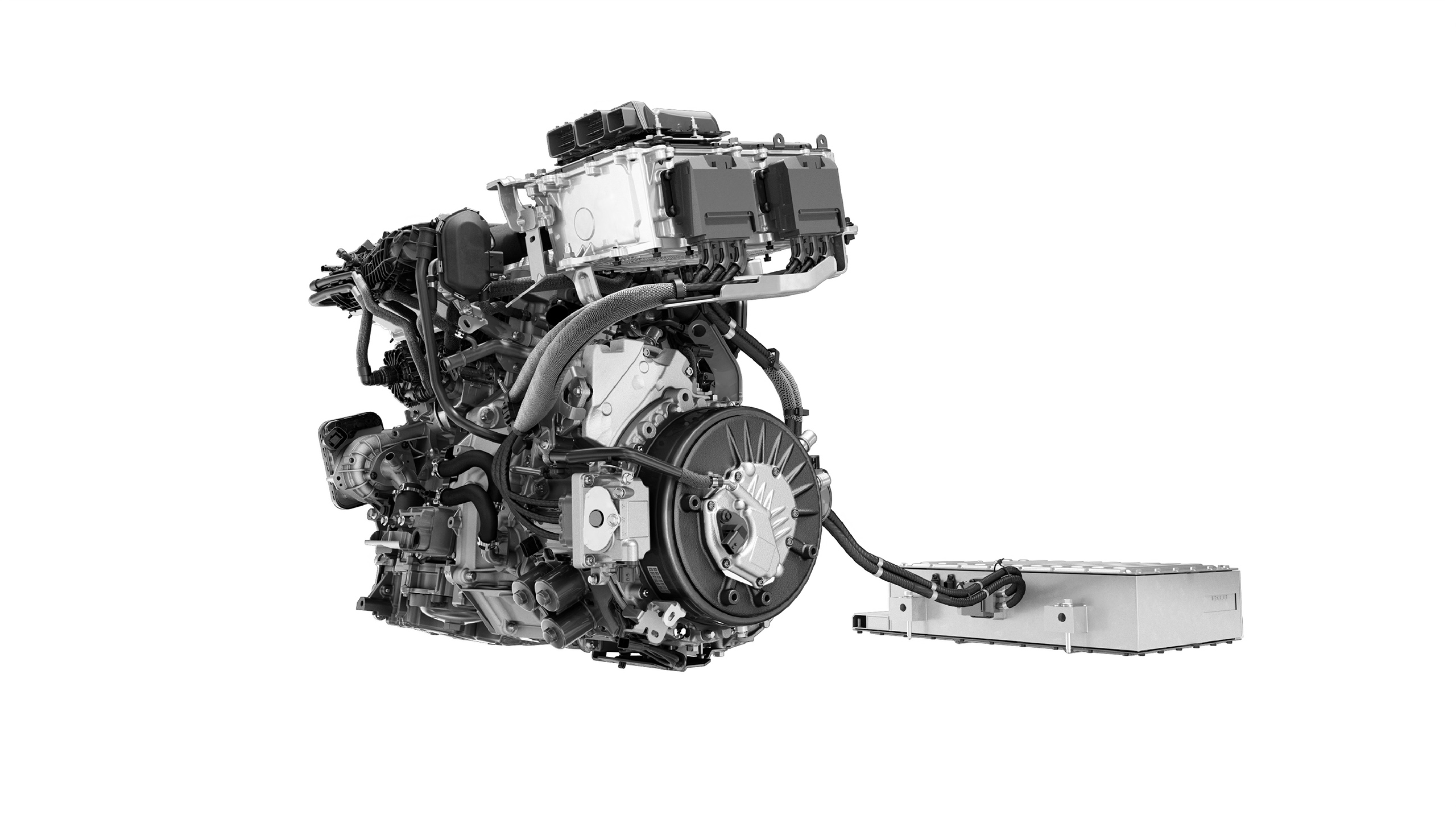

2022: Started manufacturing HR12 hybrid engines with the Full Hybrid 200 (146Kw).

2023: Reached 34 million engine milestone; the Valladolid Motores plant and engineering teams from RTS (Renault Technology Spain) became part of Horse on 1 July.