14 JUN. 2024

HORSE and WEG sign memorandum of understanding for powertrain partnership

– R&D partnership between HORSE and WEG focuses on development of Range Extender technology for light commercial and heavy duty vehicles.

– As part of the agreement, WEG to supply electric generators, e-motors, electrical inverters and battery packs

– Range Extender powertrains also can use bioethanol and flex fuels, allowing the vehicle to achieve comparable emissions to fully electric vehicles

HORSE, a global leader in innovative and low emissions powertrain systems, has signed a memorandum of understanding (MOU) with leading Brazilian electronics manufacturer, WEG for a Research & Development partnership on its new Range Extender powertrain. This commercial partnership is HORSE’s first as a division of HORSE Powertrain Ltd.

As part of this agreement, HORSE and WEG will jointly-develop a market-leading Range Extender powertrain for light commercial and heavy duty vehicles, with WEG supplying the key components for the technology.

Upon completion of the R&D study, HORSE will become the system owner and supplier to customers.

HORSE will own the electronic architecture of the Range Extender, integrating components within existing requirements, as well as supplying the 1.0-litre ‘HR10’ engine and Control Module. WEG will supply the electric generators, e-motors, and electrical inverters.

Julien Faure, Chief Technology Officer at HORSE, said: “HORSE is focused on delivering decarbonisation technologies around the world, and this partnership with WEG will help to democratise the Range Extender powertrain solution. Working with a world-class electrical technology provider like WEG demonstrates our ability to create world-class powertrain solutions for the world’s differing needs and technical requirements.”

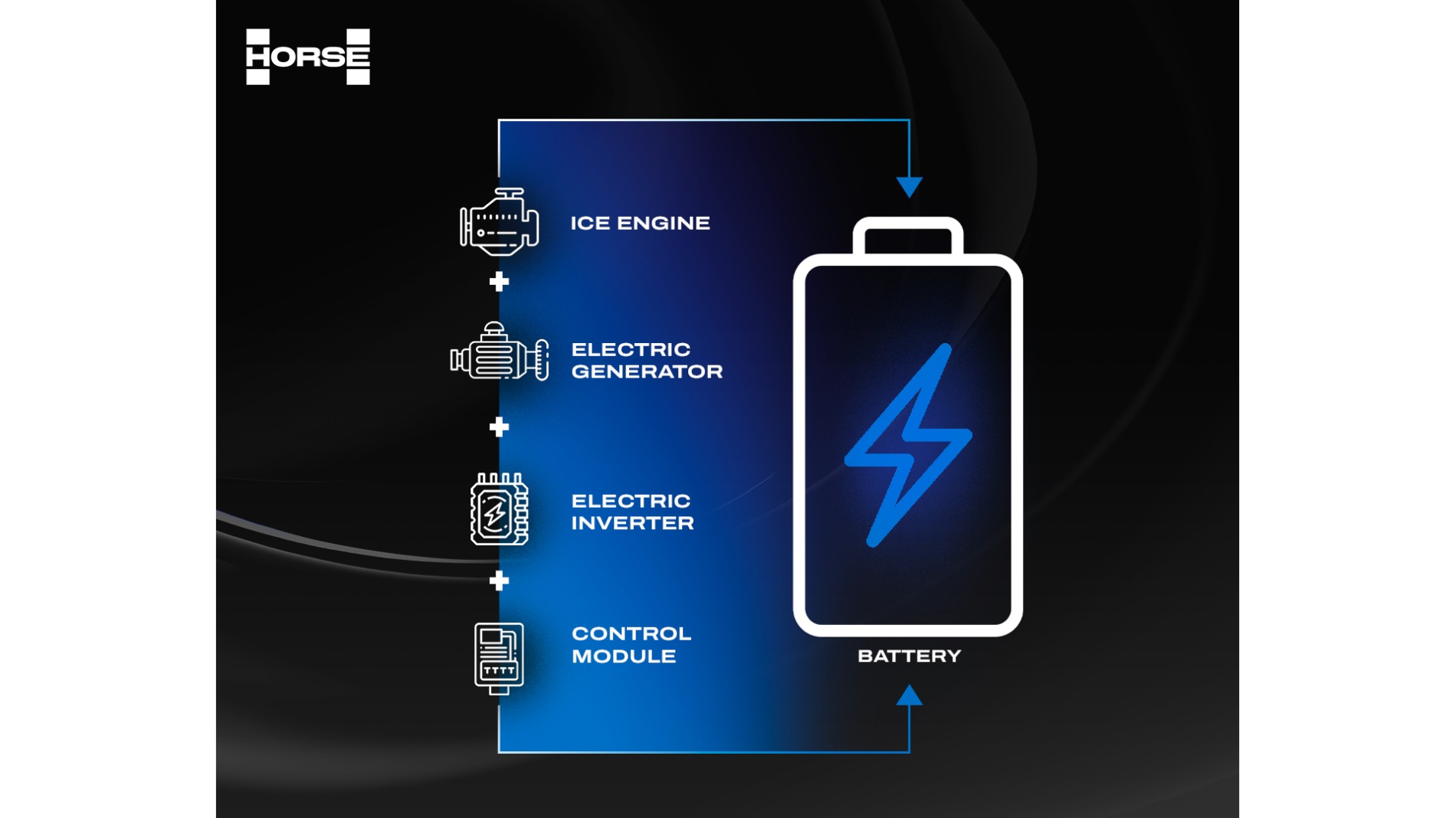

A Range Extender is made up of six key modules:

- The combustion engine, which generates mechanical energy that powers the electric generator.

- The electric generator, which converts mechanical energy from the engine into electric charge for the battery.

- The electric inverter, which converts direct current into alternating current, and enables communications between electronic components.

- The electronic control unit, which issues real-time instructions for vehicle components and electronics.

- The e-motor, which converts charge from the battery into mechanical traction for vehicle propulsion, as well as providing regenerative braking functionality.

- The battery, which stores the electrical energy originating from the electric generator and e-motor.

This partnership with WEG will grant HORSE preferential access to these critical components for its fully integrated Range Extender units, allowing continuous supply for customers. Designed for both light commercial and heavy duty vehicles, the Range Extender features an optimised battery pack and HORSE’s 85kW 1.0-litre, three-cylinder ‘HR10’ engine. The HR10 can use flex fuels, allowing the Range Extender’s total emissions profile to be comparable to that of a fully electric vehicle.

The benefit of a Range Extender is the engine constantly operates in its most efficient operating window, minimising fuel consumption and emissions.

HORSE: a leader in automotive innovation

HORSE was created to provide highly efficient, low-emission engines, transmissions, and technologies to meet the varying power generation needs around the world. HORSE operates eight production plants across seven countries, three R&D centres and a head office based in Madrid, Spain – the company produces 3.2 million units per year for its customers around the world.

DOWNLOAD DOCUMENT

10 JUN. 2024

HORSE commits to ‘2030 sustainability plan’

– HORSE unveils stringent ESG sustainability commitments as it works towards net zero by 2050

– Commitment to Net Zero Standard already submitted and approved by SBTi

– Far-reaching action plan spans network, operations and product range

– Key pillar aimed at strengthening environmental sustainability throughout the supply chain

HORSE, a global leader in innovative and low emissions powertrain systems, has launched its ambitious ‘2030 Sustainability Plan’, which commits the business to a wide range of stringent carbon-reduction and social-impact targets.

The company has already begun pursuing its pledges in its Environmental, Social and Governance (ESG) plan, with a commitment to Net Zero Standard already submitted to the SBTi (Science Based Targets initiative). The ultimate target is to become a carbon net zero sustainable mobility company by 2050.

By 2030, there are a number of key milestones that will already have been met by the company, covering operations, product range, as well as reducing emissions through the supply network.

Low emissions powertrains

A cornerstone of HORSE’s commitment is ensuring that 60% of total global sales are low-carbon engines by the end of the decade; with hybrid and flex fuel powertrains being joined by next-generation hybrid, lightweight range extenders, and synthetic and hydrogen-fuelled power solutions.

This commitment to sales of low carbon engines will result in a significant 29% decrease in emissions from sold product per kilometre (well to wheel), compared to 2023.

To achieve this, HORSE will increase the number of hybrid electric and plug-in hybrid powertrains it builds, plus add to its flex-fuel units. This includes E85 and E100 ethanol engines, as well as those powered by Compressed Natural Gas (CNG) and Liquified Petroleum Gas (LPG).

Patrice Haettel, Chief Executive Officer at HORSE, said: “We have embedded sustainability into everything we do, it is what will defines us: we are a company with a clear and firm commitment to both people and the planet. Our technologies contribute to the reduction of mobility’s carbon footprint and the energy transition needed to drive decarbonisation. We believe that we must do more than simply create low-emission propulsion solutions. We have to act as a transformation agent within the automotive sector to provide sustainable, responsible, and inclusive mobility.”

“As we move towards our 2050 goal of becoming carbon net zero, we understand there will be many challenges to overcome. However, with our spirit of innovation and expertise, along with a highly trained workforce, we are perfectly placed to achieve our ambitious goals over the coming decades.”

Positive production processes

The plan goes much further than just HORSE’s end product, with it also targeting reductions in carbon emissions at plants and its downstream network. This will result in a 42% reduction in scope 1 and 2 carbon emissions between 2023 and 2030.

By 2030, every HORSE facility around the world will use only renewable electricity to power operations. Currently, more than two-thirds of its factories already use renewable electricity.

Further improvements will be made to increase sustainability in the production process, with as much as 73% of the aluminium content being sourced from recycled materials, up from today’s figure of 66%. In addition, all production facilities will put in place a biodiversity assessment and planning processes that ensure a positive impact for the local environment.

People at its heart

At the heart of HORSE’s sustainability goals is an engaged, safe workforce that is fully committed to this journey. Within this commitment, all sites around the world will be certified under the Great Place to Work scheme.

HORSE has earmarked €3 million for social contribution projects in and around its production facilities. This funding will help empower employees and the local community to make positive impacts on their lives and nature.

Ethics as the guiding principle

HORSE will also ensure responsibility for sustainable production extends to its supply chain, with all partners being expected to meet its ESG requirements by 2030. These ethical and governance standards extend throughout its value chain and its commercial partnerships with third parties.

HORSE: a leader in Innovative Power Solutions

HORSE was created to provide highly efficient, low-emission engines, transmissions, and technologies to meet the varying power generation needs around the world. HORSE operates eight production plants across seven countries, three R&D centres and a head office based in Madrid, Spain – the company produces 3.2 million units per year for its customers around the world.

DOWNLOAD DOCUMENT

31 MAY. 2024

Renault Group and Geely announce the creation of leading Powertrain Technology Company, “HORSE Powertrain Limited”

– Following the agreements signed on July 11, 2023 by Renault Group and Geely, and after having obtained the approval of the relevant authorities, HORSE Powertrain Limited has been officially created on May 31, 2024 with each group holding 50% stake in the new company.

– The new company will lead the market for hybrid and combustion powertrain components and systems.

– Matias Giannini is appointed CEO of HORSE Powertrain limited. The Board of directors of HORSE Powertrain Limited will be chaired by Daniel Li and will have 6 directors with equal representation from its shareholders.

– HORSE Powertrain Limited expects to reach c. €15 billion in annual revenues and a production of c. 5 million powertrain units per year and will have as of day 1 a complete portfolio of state-of-the-art powertrain technologies for global partners including hybrid systems, internal combustion engines, transmissions, and battery solutions.

Following the joint venture agreement signed on July 11, 2023, and after having obtained the approval of the relevant authorities, Renault Group, Geely Holding Group (Geely Holding), Geely Automobile Holdings Limited (Geely Auto) (collectively referred to above as “Geely”) have officially created HORSE Powertrain Limited, headquartered in London, United Kingdom.

Luca de Meo, CEO Renault Group declared: “Today marks an important step in meeting the greatest challenges facing the automotive industry: the decarbonization of road transport. Partnering with a leading company like Geely to create a new player with the capability and expertise to develop ultra-low emission internal combustion engines and high economy hybrid technologies is key for the future. Through HORSE Powertrain, Renault Group can achieve worldwide leadership and scale in a sector representing more than 80% of its business. Together we will rise to meet the decarbonization challenge with innovation at the forefront of our operations.”

Eric Li, Geely Holding Chairman: “For the industry to reach net zero emissions in the next decades, global synergies, multiple technologies, and sharing of expertise, are crucial. That is why we are pleased that our partnership with Renault Group is reaching commercial reality today. HORSE Powertrain Limited will have the portfolio, scale and capacity to offer the low-emission solutions the automotive industry of tomorrow demands. Today’s launch marks a new chapter in sustainable mobility, and we at Geely are proud to play a part.”

Renault Group and Geely believe that a combination of various powertrain technologies is necessary, including highly efficient internal combustion engines (ICE), lower carbon e-fuels, and hydrogen, to achieve a successful decarbonization in a world where more than half of vehicles produced are expected to still rely on combustion engines by 2040.

A new player to disrupt the game and pave the way for ultra-low emission hybrid and combustion technologies.

HORSE Powertrain Limited will design, develop, produce, and sell all hybrid and combustion powertrain solutions and systems with state-of-the-art technologies including engines, transmissions, hybrid systems and batteries.

Thanks to this project, both Renault Group and Geely will benefit from immediate scale effect and market coverage enhancement. Supported by the transfer of Intellectual Property from Renault Group and Geely, HORSE Powertrain Limited is now fully autonomous in developing future powertrain technologies capable of addressing all market expectations, notably in the field of alternative fuels such as green methanol, ethanol, and hydrogen. The joint venture’s complementary product portfolio and regional footprint could offer solutions for 80% of the growing global hybrid & combustion powertrain market.

HORSE Powertrain will supply multiple industrial customers including Renault Group, Geely Auto, Volvo Cars, Proton, Nissan and Mitsubishi Motors Company. The company is ready to engage with customers and partners around the world to support them with end to end solutions in powertrain technologies and will welcome partners to further strengthen the value chain.

From Day One of its establishment, HORSE Powertrain Limited is worldwide leader in hybrid and combustion powertrain solutions with:

- 17 global plants

- 9 customers in 130 countries

- 5 R&D centers

- c.19,000 employees

- expected c. €15 billion in yearly revenues

- expected c.5 million units powertrain per year

- All types of hybrid solutions covered – full hybrids and long-range plug-in hybrids as well as internal combustion engines that use alternative fuels such as ethanol, methanol, LPG, CNG, H2 etc.

Governance structure

Renault Group and Geely, as funding shareholders of the powertrain company, have approved the global governance scheme as well as strategic appointments of HORSE Powertrain Limited.

Matias Giannini is appointed CEO of HORSE Powertrain Limited.

Lee Ma and Juan Ferrera are respectively appointed Chief Financial Officer and Chief Human Resources Officer of HORSE Powertrain Limited.

The management of the two subgroups Aurobay and Horse, bringing together the industrial know-how and assets of both companies remains unchanged: Ruiping Wang as CEO of Aurobay, based in Hangzhou Bay (China), Patrice Haettel CEO of Horse based in Madrid (Spain). They will directly report to Matias Giannini.

The board of directors of HORSE Powertrain Limited is composed of 6 members:

- Three directors from Geely: Daniel Li (Vice Chairman of Geely Auto and CEO of Geely Holding) will become chairman of the Board, Jerry Gan (CEO of Geely Auto Group) and Joe Zhang (Chief Financial Officer of Geely Holding).

- Three directors from Renault Group: François Provost (Chief Procurement, Partnerships and Public Affairs Officer), Gilles Le Borgne (Chief Technology Officer) and Denis Le Vot (CEO of Dacia and Chief Supply Chain Officer).

As of May 31, 2024, the respective operational entities of HORSE Powertrain Limited, namely Horse and Aurobay, will be deconsolidated respectively from Renault Group and Geely.

DOWNLOAD DOCUMENT

18 APR. 2024

HORSE reveals its pioneering fully digital ‘Matrix Flow’ production process

– HORSE unveils its innovative and fully digital Matrix Flow production line

– Cutting edge autonomous platforms replace traditional conveyor belt production line

– Pioneering technology used to build Power Electric Boxes for HEV and PHEV vehicles

– Advanced systems deliver greater flexibility and productivity in the move to electrification

– Huge energy savings of up to 50% as a result of faster and more streamlined processes

HORSE, a global leader in innovative and low emissions powertrain systems, is pioneering an advanced, fully digital automated production process aimed at enhancing productivity, quality and sustainability in its factories.

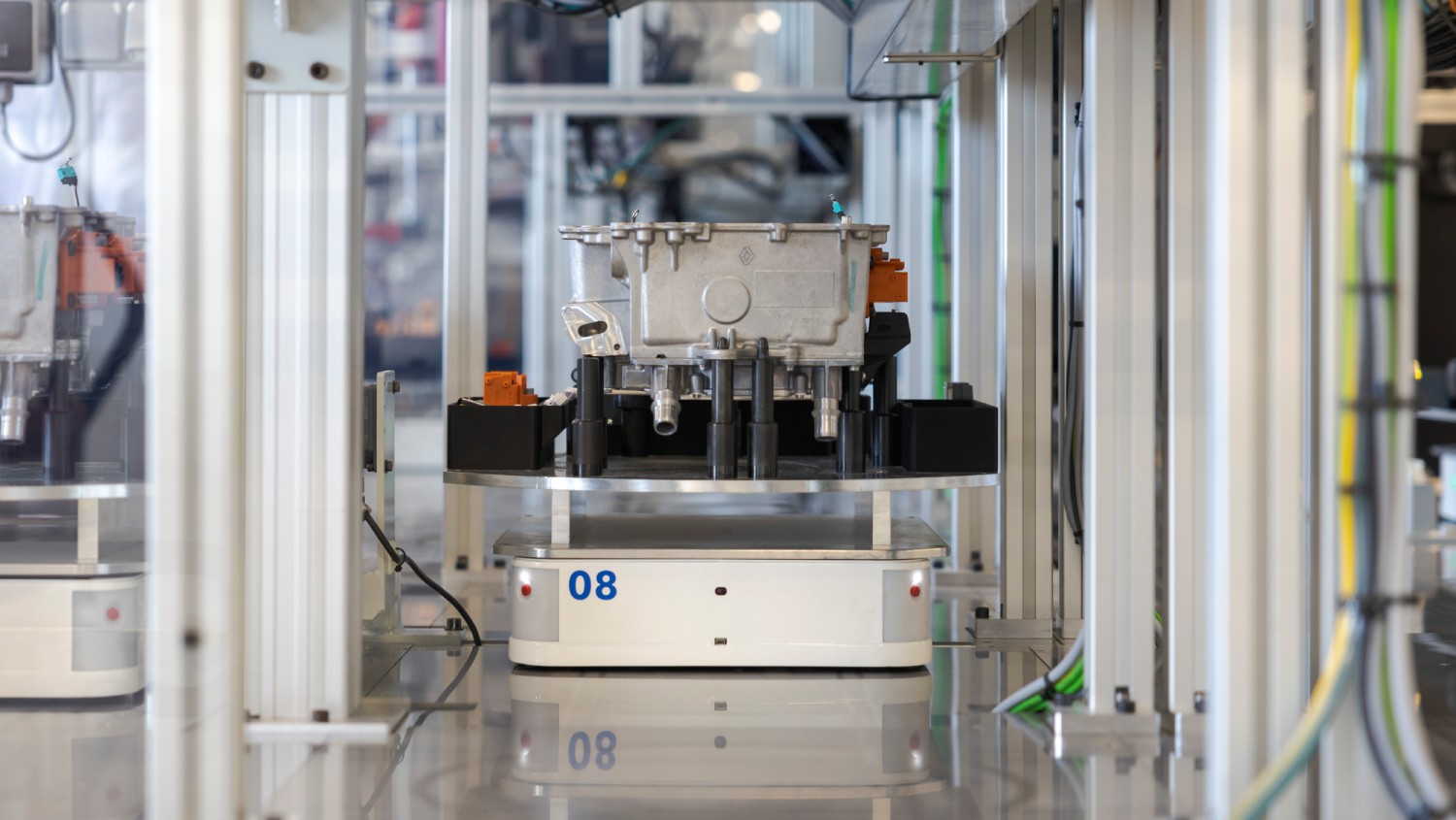

Known as Matrix Flow, the new process debuts in HORSE’s Aveiro plant in Portugal. It replaces the existing, sequential conveyor belt-based production system with a highly efficient fleet of autonomous platforms and work stations known as Mobile Programmable Cobots (MPCs).

Already used in the manufacture of electronic goods and by multi-national logistics firms, HORSE is one of the first companies to tailor the process for automotive powertrain production using it to construct the Power Electronic Box (PEB) that manage the electric motors in Hybrid Electric Vehicles (HEV) and Plug-in Hybrid Electric Vehicles (PHEV).

Antonio Vaz, Chief Process Engineering Officer at HORSE said: “Our new Matrix Flow Assembly line at Aveiro is a hugely significant moment for HORSE. This exciting development confirms our place as a global leader in powertrain development and production. By delivering unrivalled flexibility and efficiency, this fully digital production method allows us to be agile and responsive while continuing to deliver the highest quality products and meet our commitments to sustainable mobility.”

Developed in partnership with automated production specialists Prolynk (a project by OSE Group), these MPC can deliver the precise components and sub-assemblies needed to factory staff and robots at each stage of the production process. Up to 30 smaller MPC effectively act as mobile workstations and components kitting, ensuring employees always have the right parts and tools at the right time.

Managed by a carefully programmed fleet controller hub, the MPC wirelessly communicate with each other and can quickly adapt to changes in parts supply and production needs, delivering greater flexibility in the production process as well as huge reductions in costly downtime. It can also be quickly scaled up or down, allowing the factory to react quickly to changes in demand.

Production of PEB at the plant will start in the coming days, with an initial target of 150,000 units a year, rising to 200,000 by the end of 2024.

Enhanced Efficiency

By using the autonomous MPCs instead of a traditional sequential flow production line, HORSE has been able to reduce the physical footprint of its factory floor by 25%, and the size of the building overall by 30%.

With a smaller facility and streamlined production, HORSE has been able to slash energy use at the site by a significant 50%. Paper labels are also no longer required for any component as each is digitally identified, delivering more accurate and sustainable production.

Ready for an electrified future

HORSE’s Matrix Flow concept puts it at the forefront of production technology as the automotive industry transitions to a fully electrified future. Without the need for a fixed production line, HORSE can quickly and efficiently scale production up or down to accept updated components or even a completely new product.

The Aveiro facility has been designed to deliver a clean, sterile and electro-static discharge (ESD) environment, crucial to the production of high technology electric powertrains. Effectively creating a ‘cocoon’ around the production line, this approach ensures the quality of the products and the safety of the staff.

HORSE has also invested heavily in its production staff, providing training that allows them to adopt the latest techniques and technologies. For instance, the use of virtual reality goggles and bespoke software allows employees to quickly and safely adapt to any changes in the Matrix Flow production processes before they’re implemented.

HORSE: a leader in Innovative Powertrain Solutions

HORSE was created to provide highly efficient, low-emission engines, transmissions and technologies to meet the varying power generation needs around the world. HORSE is a truly global company, with eight production plants across seven countries, three R&D centres and a head office based in Madrid, Spain. The company produces 3.2 million units per year for its customers around the world.

Since its creation less than a year ago, HORSE has maintained an upward trajectory, thanks to its strong focus on R&D and cutting-edge technology as well as its ability to form new commercial partnerships.

DOWNLOAD DOCUMENT

16 APR. 2024

HORSE commences power electronics box production at Aveiro

– Production of Power Electronics Box begins today in Aveiro, Portugal, with production expected to reach 230,000 per annum from 2025.

– Power Electronic Box – redesigned with fewer wiring harnesses – integrates power inversion, conversion, control, and cooling systems into a single unit.

– New assembly line uses state-of-the-art technology for full digitalisation and innovative industry 4.0

HORSE, a global leader in innovative and low emissions powertrain systems, today announces the start of production of its Power Electronics Box (PEBs) at its plant in Aveiro, Portugal.

The PEB is a major component in the value chain for hybrid vehicle powertrains and is responsible for managing the two electric motors in all of HORSE’s hybrid (HEV) and plug-in hybrid (PHEV) systems. The device, which has been redesigned simplifying components for increasing robustness and reliability, integrates several critical systems into a single unit, encompassing:

- Power inverter/converter, converting direct current (DC) from the High Voltage battery into alternating current (AC) for driving the electric motors of the powertrain.

- DC/DC converter, converting high-voltage DC battery energy into low-voltage DC to the 14V network for use in various sub-systems across the car, including lights, radio, and charge for the smaller 12V battery.

- Control electronics, providing real-time regulation for power distribution across the vehicle based on velocity and acceleration.

- Cooling, with the PEB ensuring that all components avoid overheating, maximising the unit’s service life and improving efficiency.

Patrice Haettel, Chief Executive Officer of HORSE, said: “The start of Power Electronic Box production in Aveiro marks a significant milestone as it signifies the transition towards electronic component manufacturing for HORSE in Portugal. Additionally, we are using an innovative production process which it enables us to have a significant competitive advantage. This substantially increases our production capacity, ensuring that we can deliver key hybrid vehicle technologies to our customers worldwide. The Aveiro production line enhances our flexibility and productivity while serving as a beacon of Industry 4.0, reaffirming our position as a leading provider of low-carbon combustion and hybrid powertrain systems.”

Production at Aveiro

HORSE’s plant in Aveiro, Portugal, was chosen to be the company’s site for PEB production owing to its industrial performance. With more than forty years of operational excellence in manufacturing gearboxes and engines, this new venture marks Aveiro’s first step into producing electronic components. It has a number of sustainability projects that reduce its carbon footprint, including having the largest private photovoltaic field in Portugal, as well as being situated in close proximity to its customers.

Raynald Joly, Plant Director at HORSE Aveiro, said: “With a 1,300-strong workforce, the Aveiro plant is an outstanding centre of skills and technology that’s ideally placed to serve customers as the primary site for manufacturing such an important product within hybrid vehicles. With over forty years as a world-leading automotive manufacturing site, this new production along with our ongoing transformation plan will confirm the status of HORSE Aveiro as a new innovative technology business unit for and beyond automotive industry.”

HORSE expects the Aveiro facility to produce 60,000 units on its new assembly line this year. The assembly line is the first at the plant to be converted into an electro-static discharge protected area (EPA), designed to minimise electro-static charge and ensure quality and safety. In 2025, HORSE expects the line to increase production to 230,000 PEB units. The project is the culmination of significant investment by HORSE, with the PEB project team having transformed a former warehouse into a cutting-edge electronics manufacturing site in less than one year.

In anticipation of production, HORSE has invested in state-of-the-art training for staff in Aveiro. Along with training for ESD-safe environments, staff working on the PEB assembly line have also trained on virtual reality (VR) simulations. The line itself leverages a range of modern industrial innovations: autonomous geolocation-powered platforms to carry parts across the workshop, full digital control of all operations, and real-time monitoring of all critical parameters.

HORSE: a leader in Innovative Powertrain Solutions

HORSE was created to provide highly efficient, low-emission engines, transmissions and technologies to meet the varying power generation needs around the world. HORSE is a truly global company, with eight production plants across seven countries, three R&D centres and a head office based in Madrid, Spain. The company produces 3.2 million units per year for its customers around the world.

Since its creation less than a year ago, HORSE has maintained an upward trajectory, thanks to its strong focus on R&D and cutting-edge technology as well as its ability to form new commercial partnerships.

DOWNLOAD DOCUMENT

28 MAR. 2024

HORSE supplies low-emission engine to Chilean innovative electric bus manufacturer, Reborn Electric Motors

– HORSE has supplied its first engine to REBORN Electric Motors, one of the leading electric bus factories in the region

– 1.0-litre engine will power Range Extender technology within the vehicle, to be used across South America

– HORSE selected as supplier due to expertise in local Curitiba production facility

– HORSE and REBORN Electric Motors share the goal of helping to accelerate decarbonisation of the transport industry

HORSE, a global leader in innovative powertrain solutions, has delivered the first engine to REBORN Electric Motors aimed at making transport more sustainable in South America.

HORSE was chosen because of its local-market expertise and volume production that can guarantee long-term supply to REBORN Electric Motors, which builds and renovates buses for Chile.

The 1.0-litre 3-cylinder turbo petrol engine, produced at the company’s Curitiba, Brazil facility, has been fitted to a 24-seat bus with Range Extender technology.

The engine has peak power of 86kW @ 5,000 rpm and reaches maximum torque of 200Nm @ 1,750 rpm. The range extender takes energy from the engine and charges the on-board battery, with the battery providing electricity to power the electric motor which drives the wheels.

Patrice Haettel, Chief Executive Officer at HORSE, said: “This is an incredibly important moment for our business as we’re going beyond supplying our core automotive partners and entering another exciting mobility sector in South America. We’re creating tailormade, low-emission solutions that support the pace of change, and the technical needs of global markets as we transition to a more sustainable future. REBORN is benefitting from our global footprint that delivers both world-class production and testing facilities.”

The HORSE Curitiba plant encompasses a powertrain plant and foundry, one of the largest industrial bases in South America. It produces both 1.0-litre (BR10) and 1.6-litre (HR16) powertrains, as well as crankshafts, cylinder heads and engine blocks. The on-site foundry die-casts aluminium engine blocks and cylinder heads.

Felipe Cevallos Becker, Chief Executive Officer at REBORN Electric Motors, added: “Our goal is to accelerate the migration to a more sustainable mobility, creating new solutions for the Latin American market. HORSE was the perfect partner with its local market knowledge and ability to quickly respond to this exciting opportunity to create a new low emission vehicle for the market.”

HORSE: a leader in Innovative Power Solutions

Since its creation less than a year ago, HORSE has maintained an upward trajectory, thanks to its strong focus on R&D, and its ability to form new commercial partnerships.

HORSE was created to provide highly efficient, low-emission engines, transmissions and technologies to meet the varying power generation needs around the world. HORSE is a truly global company, with eight production plants across seven countries, three R&D centres and a head office based in Madrid, Spain. The company produces 3.2 million units per year for its customers around the world.

REBORN Electric Motors

REBORN Electric Motors specializes in sustainable transport for commercial vehicles and public transport in Latin America. The company pioneers a novel electromobility solutions tailored to the needs of the Latin American market, offering a fleet of fully electric and hydrogen-powered buses. In addition, it retrofits diesel buses with new electrified powertrains which both reduces carbon dioxide (CO2) emitted during operation, as well as extending the lifespan of the vehicle.

REBORN Electric Motors, founded by a group of engineers from universities across Chile, has a research & development facility in Rancagua, Chile with the focus on development of future sustainable mobility.

HORSE and REBORN Electric Motors share the goal of helping to accelerate decarbonisation of the transport industry.

DOWNLOAD DOCUMENT

08 FEB. 2024

HORSE and Dumarey Group sign Strategic Agreement

HORSE, a global innovation partner for powertrain solutions, has signed a strategic agreement with Dumarey Group. The partnership is based on HORSE’s extensive experience in engine production and Dumarey Automotive Italia SPA (formerly PUNCH Torino) expertise in advanced propulsion systems and embedded controls.

As part of the new agreement, HORSE and Dumarey Automotive Italia will co-develop HORSE’s flagship 2.0-litre four-cylinder turbodiesel engine (M920) with manual transmission, readying it for Euro7 front-wheel drive and EuroVI rear-wheel drive applications.

This agreement will set the foundation for further potential future cooperations between the Parties on low carbon fuels, including hydrogen-fueled internal combustion engines, for which the Dumarey Group, through its brand Hydrocells, has gained a considerable expertise.