16 APR. 2024

HORSE commences power electronics box production at Aveiro

– Production of Power Electronics Box begins today in Aveiro, Portugal, with production expected to reach 230,000 per annum from 2025.

– Power Electronic Box – redesigned with fewer wiring harnesses – integrates power inversion, conversion, control, and cooling systems into a single unit.

– New assembly line uses state-of-the-art technology for full digitalisation and innovative industry 4.0

HORSE, a global leader in innovative and low emissions powertrain systems, today announces the start of production of its Power Electronics Box (PEBs) at its plant in Aveiro, Portugal.

The PEB is a major component in the value chain for hybrid vehicle powertrains and is responsible for managing the two electric motors in all of HORSE’s hybrid (HEV) and plug-in hybrid (PHEV) systems. The device, which has been redesigned simplifying components for increasing robustness and reliability, integrates several critical systems into a single unit, encompassing:

- Power inverter/converter, converting direct current (DC) from the High Voltage battery into alternating current (AC) for driving the electric motors of the powertrain.

- DC/DC converter, converting high-voltage DC battery energy into low-voltage DC to the 14V network for use in various sub-systems across the car, including lights, radio, and charge for the smaller 12V battery.

- Control electronics, providing real-time regulation for power distribution across the vehicle based on velocity and acceleration.

- Cooling, with the PEB ensuring that all components avoid overheating, maximising the unit’s service life and improving efficiency.

Patrice Haettel, Chief Executive Officer of HORSE, said: “The start of Power Electronic Box production in Aveiro marks a significant milestone as it signifies the transition towards electronic component manufacturing for HORSE in Portugal. Additionally, we are using an innovative production process which it enables us to have a significant competitive advantage. This substantially increases our production capacity, ensuring that we can deliver key hybrid vehicle technologies to our customers worldwide. The Aveiro production line enhances our flexibility and productivity while serving as a beacon of Industry 4.0, reaffirming our position as a leading provider of low-carbon combustion and hybrid powertrain systems.”

Production at Aveiro

HORSE’s plant in Aveiro, Portugal, was chosen to be the company’s site for PEB production owing to its industrial performance. With more than forty years of operational excellence in manufacturing gearboxes and engines, this new venture marks Aveiro’s first step into producing electronic components. It has a number of sustainability projects that reduce its carbon footprint, including having the largest private photovoltaic field in Portugal, as well as being situated in close proximity to its customers.

Raynald Joly, Plant Director at HORSE Aveiro, said: “With a 1,300-strong workforce, the Aveiro plant is an outstanding centre of skills and technology that’s ideally placed to serve customers as the primary site for manufacturing such an important product within hybrid vehicles. With over forty years as a world-leading automotive manufacturing site, this new production along with our ongoing transformation plan will confirm the status of HORSE Aveiro as a new innovative technology business unit for and beyond automotive industry.”

HORSE expects the Aveiro facility to produce 60,000 units on its new assembly line this year. The assembly line is the first at the plant to be converted into an electro-static discharge protected area (EPA), designed to minimise electro-static charge and ensure quality and safety. In 2025, HORSE expects the line to increase production to 230,000 PEB units. The project is the culmination of significant investment by HORSE, with the PEB project team having transformed a former warehouse into a cutting-edge electronics manufacturing site in less than one year.

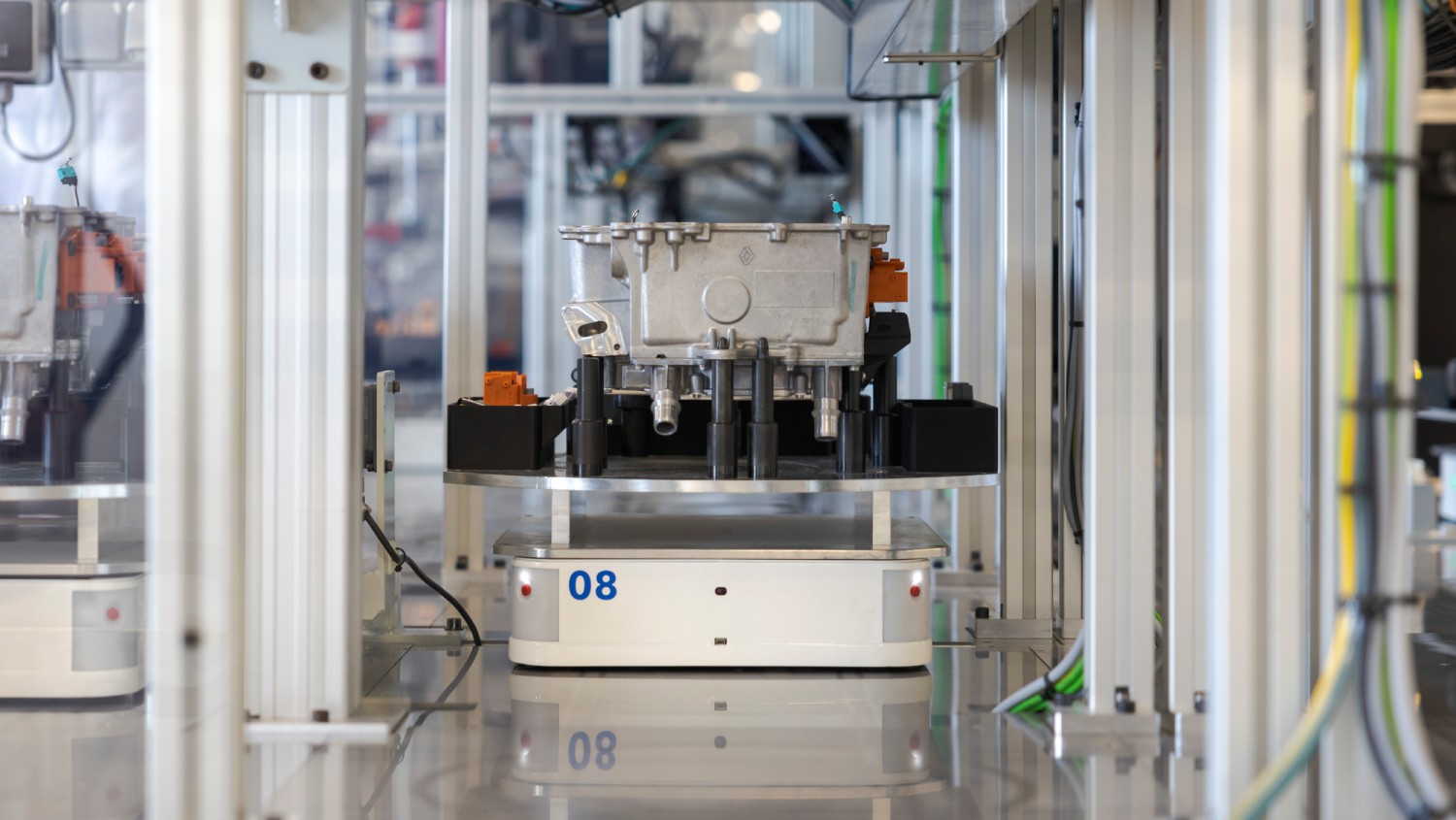

In anticipation of production, HORSE has invested in state-of-the-art training for staff in Aveiro. Along with training for ESD-safe environments, staff working on the PEB assembly line have also trained on virtual reality (VR) simulations. The line itself leverages a range of modern industrial innovations: autonomous geolocation-powered platforms to carry parts across the workshop, full digital control of all operations, and real-time monitoring of all critical parameters.

HORSE: a leader in Innovative Powertrain Solutions

HORSE was created to provide highly efficient, low-emission engines, transmissions and technologies to meet the varying power generation needs around the world. HORSE is a truly global company, with eight production plants across seven countries, three R&D centres and a head office based in Madrid, Spain. The company produces 3.2 million units per year for its customers around the world.

Since its creation less than a year ago, HORSE has maintained an upward trajectory, thanks to its strong focus on R&D and cutting-edge technology as well as its ability to form new commercial partnerships.